How Do Cable Ties Work: Nylon Self Locking Design Explained

Introduction

Nylon self locking cable tie, also known as self locking zip ties, is a practical tool widely used in both daily life and industrial environments. Whether organizing household appliance wires or managing cables in large industrial equipment, it plays a crucial role. With the continuous progress of industrial technology, nylon self locking cable ties have gradually become the mainstream choice in the market. They are not only simple in structure, easy to install, and cost effective, but also widely favored by users. Understanding how this type of locking zip tie works and its key advantages helps us make smarter choices and use them more effectively.

What is Nylon Self Locking Cable Tie?

A nylon self locking cable tie is a fastening tool that relies on its built in teeth and locking mechanism to achieve one way self locking. Looking back in history, who invented zip ties? In the 1950s, as the aviation industry developed, bundling wires in aircraft cabins became a challenge. Zip ties were invented to solve this problem. With the expansion of applications, they are now widely used in electronics, power systems, automotive manufacturing, construction, marine, and photovoltaic industries, becoming a mainstream and efficient bundling solution. Their main functions are to quickly secure objects, serve as identification or decoration, and provide simple operation.

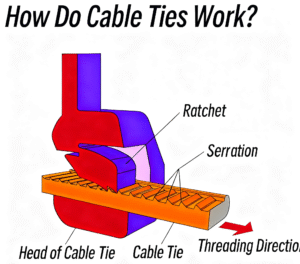

How Do Cable Ties Work

The structure of a nylon self locking cable tie consists of two parts: the strap and the head. One side of the strap is covered with evenly distributed teeth, while the head contains a ratchet locking tongue. During use, when the toothed strap is inserted into the head ratchet, the tab engages with the teeth, creating a one way lock. No additional tools are needed for installation. This self locking design prevents the ziptie from loosening in reverse, ensuring that the bundle stays secure for a long time. Even under continuous vibration or external pulling, it maintains tightness without coming undone.

Advantages of Nylon Material

Nylon self locking zip ties are mainly made from PA6, PA66, PA12, and PA46 materials. PA66 combines high tensile strength and toughness with excellent resistance to both high and low temperatures (dynamic temperature range -20℃ to 85℃), making it one of the most widely used materials for plastic cable zip ties. PA6 is more affordable, PA12 is suitable for low temperature environments, and PA46 performs better in high temperature outdoor conditions. In addition, nylon is non toxic, eco friendly, recyclable, and aligned with green production standards.

Comparison of Different Cable Ties

| Type | Advantages | Disadvantages | Application |

|---|---|---|---|

| self locking cable tie | Easy to use, high tensile strength | Not reusable, difficult to remove | Household and industrial general use |

| adjustable zip ties | Releasable, reusable | Lower tensile strength, only for temporary use | Temporary bundling, adjustable needs |

| ball lock stainless steel cable tie | High strength, heat and corrosion resistance | More expensive, harder to install and remove | High temperature, chemical, long term outdoor use |

Key Features of Nylon Cable Tie Self Locking

- Easy installation: Simply insert the strap into the head and tighten, no tools required.

- High tensile strength: The one way self locking design provides better strength compared to reusable zip ties.

- Good toughness: Nylon 6 and Nylon 66 absorb some moisture, which helps resist impact and bending.

- Low cost: Automated mass production reduces manufacturing costs.

Application Scenarios

Cable management

In homes, offices, and data centers, self locking nylon cable ties are widely used to bundle messy wires, keeping cabling neat and organized. They reduce tangling and accidental pulls, improving electrical safety.

Automotive industry

In vehicle manufacturing and repair, self locking nylon cable ties are used to secure wire harnesses, hoses, and small components. Their abrasion resistance and anti vibration properties ensure stability even during driving vibrations, improving safety.

Construction sites

In the construction industry, self locking nylon cable zip ties are used for temporary fastening, such as bundling rebar, stabilizing formwork, or organizing scaffolding accessories. Their simple operation and good load capacity provide reliable support and improve efficiency.

Outdoor use

With strong weather resistance, self locking nylon cable zip ties maintain stable performance under sun, rain, and harsh conditions. They are commonly used for outdoor facilities such as fixing solar panels, supporting plants in gardening, or repairing camping gear.

FAQ

Q1: Can nylon self locking zip ties be reused?

Most are single use, but some designs include a release tab, allowing multiple uses. For example, in northern China, extra long zip ties of 1m or 1.2m are used for bundling corn stalks and can be reused several times.

Q2: How long can nylon self locking zip ties last outdoors?

It depends on the nylon material used. Generally, from longest to shortest: PA46 > PA66 > PA6.

Q3: What are the common reasons for nylon self locking cable ties breaking?

Exceeding maximum tensile strength, aging due to sun and rain, poor material quality, or production defects may cause breakage.

Conclusion

Nylon self locking cable ties are widely used tools. Their self locking design secures cables and components tightly without loosening. They are easy to use, cost effective, durable, and suitable for household, industrial, and outdoor applications. Choosing the right size and material improves efficiency and reduces long term maintenance costs, making them an essential accessory.