What are polypropylene cable ties?

Product Introduction

Polypropylene cable ties, often referred to as PP cable ties, are self-locking straps made from polypropylene material. Compared to common nylon cable ties, pp cable ties offer greater resistant to chemicals, lower moisture absorption, and better recyclability. These features make them particularly suitable for demanding sectors such as chemical processing, nuclear power, and marine applications, where environmental conditions are a key concern.

If your project involves exposure to acids, alkalis, solvents, or high humidity, PP cable ties provide a dependable fastening solution.

Key Advantages

1. Excellent chemical resistant

pp cable ties show outstanding resistant to strong acids, bases, and common organic solvents, with little risk of corrosion or degradation. Even with long-term exposure to chemical media, they maintain stable mechanical properties, making them ideal for corrosive environments such as chemical plants, electroplating workshops, and laboratories.

2. Low water absorption, stable performance

Compared with traditional nylon cable ties, PP material absorbs almost no moisture, effectively avoiding problems such as softening or reduced tensile strength caused by humidity. Even under continuous water immersion, they maintain fastening force and structural integrity, suitable for ships, water utilities, and humid outdoor environments.

3. Eco-friendly and recyclable

Polypropylene is a thermoplastic that can be easily recycled and reused, reducing environmental impact. Choosing PP cable ties helps enterprises achieve green supply chain goals and comply with international environmental regulations and low-carbon development trends.

4. Low density, floatable, easy for water operations and recovery

pp cable ties have a lower density than water and can float on the surface for extended periods. This makes them highly suitable for aquaculture, maritime operations, and water monitoring. Even under strong water impact or fluid accumulation, the ties remain visible and easy to recover, effectively reducing loss and pollution. Especially in nuclear power plants, polypropylene cable ties can be quickly identified and removed during foreign object detection.

Technical Parameters

MATERIAL: Polypropylene

Flammability of raw material: UL 94HB

Installation temperature: -10°C ~ +80°C

Excellent acid and alkali resistant, high strength mechanical properties, and good wear resistant.

Color: Usually orange for easy identification, other colors customizable.

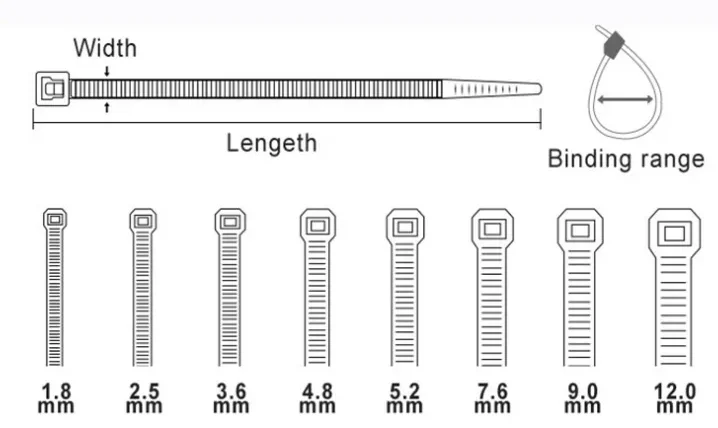

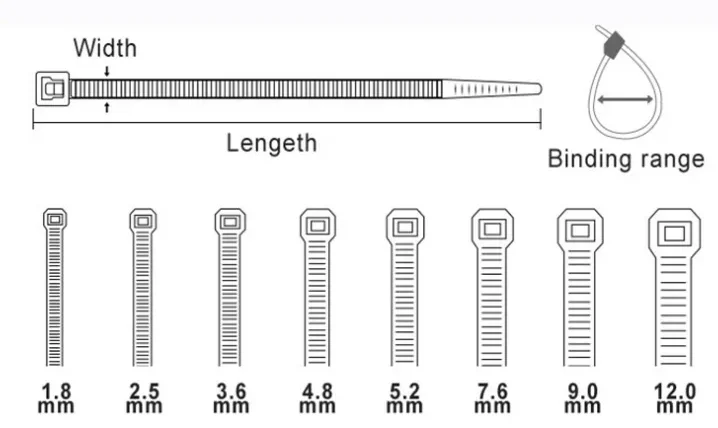

| Type | Length (mm) | Width (mm) | Max. Bundle Dia. (mm) | Min. Tensile Strength |

|---|---|---|---|---|

| WD-3x100PP | 100 | 2.5 | 22 | 6kg |

| WD-3x150PP | 150 | 2.5 | 35 | 6kg |

| WD-3x200PP | 200 | 2.5 | 50 | 6kg |

| WD-4x150PP | 150 | 3.6 | 35 | 14kg |

| WD-4x200PP | 200 | 3.6 | 50 | 14kg |

| WD-4x250PP | 250 | 3.6 | 65 | 14kg |

| WD-5x200PP | 200 | 4.8 | 50 | 17kg |

| WD-5x250PP | 250 | 4.8 | 65 | 17kg |

| WD-5x300PP | 300 | 4.8 | 82 | 17kg |

| WD-8x250PP | 250 | 7.6 | 65 | 40kg |

| WD-8x300PP | 300 | 7.6 | 82 | 40kg |

Applications

Chemical and pharmaceutical industries

polypropylene zip ties have excellent chemical resistant, effectively resisting acids, bases, and solvents. This prevents degradation and loosening, ensuring safety and neatness in critical areas such as laboratories and chemical plants.

Nuclear and marine operations

polypropylene zip ties float on water, making them suitable for nuclear cooling systems, marine equipment marking, and offshore construction. They are easy to recover, reducing pollution and equipment damage.

Marine and underwater use

Unlike nylon, polypropylene zip ties absorb almost no water. They maintain strength and stability even under long-term immersion, suitable for ships, underwater sensors, and wastewater facilities.

Eco-friendly and recyclable

polypropylene zip ties are fully recyclable, supporting circular economy goals. Widely used in projects requiring frequent replacement, they help reduce waste and enhance sustainability.

Comparison with Other Materials

| Property | polypropylene cable ties | Nylon 6/66 cable tie | Stainless Steel cable tie |

|---|---|---|---|

| Chemical resistant | ★★★★★ | ★★★ | ★★★★ |

| Tensile strength | ★★★ | ★★★★ | ★★★★★ |

| Water absorption | Very Low | Medium | None |

| Cost | High | Low | Medium |

| Typical applications | Chemical, marine, humid environments | General wiring | Extreme heat, heavy industry |

FAQ

Q1: Do you support customization?

Yes, polypropylene cable ties can be customized in color, printing, and packaging for OEM/ODM requirements.

Q2: Are polypropylene cable ties suitable for acid and alkali environments?

Yes, chemical resistant cable ties provide excellent resistant and are suitable for acids, bases, and most organic solvents.

Q3: Can I order other sizes apart from those listed?

Yes, as long as minimum order quantities are met, we can produce existing mold sizes and also support custom molds.

Q4: Do you provide samples for testing?

We provide free samples, you only need to cover the shipping cost.