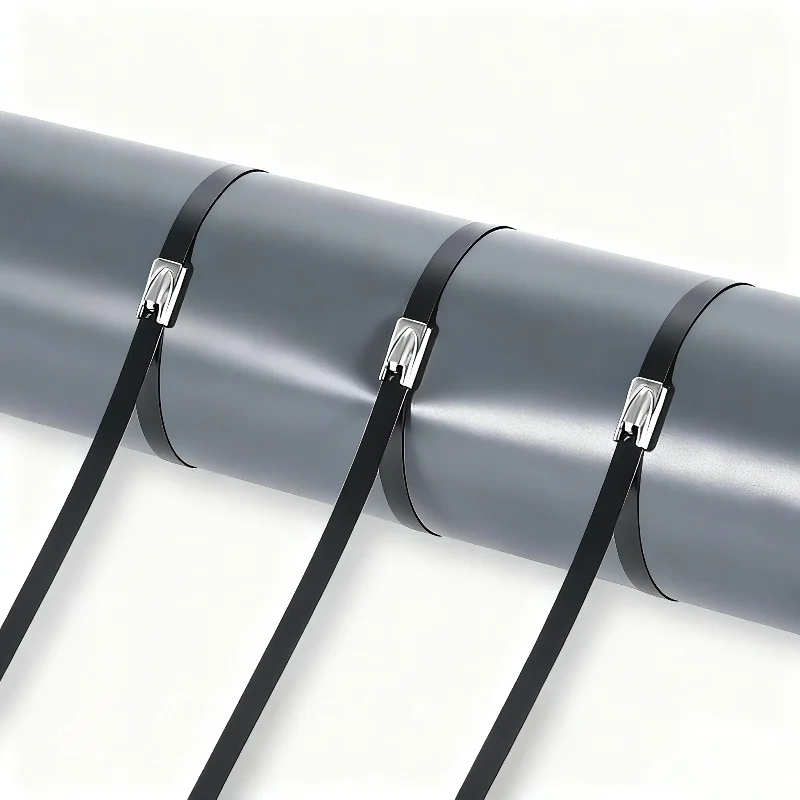

What Are Coated Stainless Steel Cable Ties?

Coated stainless steel cable ties, also known as coated wire ties, are fastening tools that feature a protective coating such as epoxy or PVC over a stainless steel base. Stainless steel cable ties coated not only maintain the high tensile strength of stainless steel but also provide excellent corrosion resistance, wear resistance, and electrical insulation. They are ideal for harsh environments such as high-corrosion areas, high temperatures, outdoor applications, and installations with electrical safety requirements. These ties are widely used for securing cables, pipes, and industrial equipment.

Structure Composition

Coated stainless steel cable ties usually consist of three parts:

- Inner Band: Made of 304 or 316 stainless steel, providing the necessary tensile strength and load-bearing capacity for a secure hold.

- Lock Head: Commonly uses a ball lock or self-locking mechanism to ensure firm fastening under vibration or high pressure.

- Surface Coating: Usually made of epoxy resin or polyethylene, enhancing corrosion resistance and protection against environmental aging.

Material Analysis

1. Base Material of Coated Stainless Steel Cable Ties

- 304 Stainless Steel: Offers reliable corrosion and oxidation resistance, suitable for general industrial and outdoor use.

- 316 Stainless Steel: Contains added molybdenum, providing superior acid and chloride corrosion resistance, ideal for marine, petrochemical, and coastal environments.

2. Coating Materials

- Epoxy Resin Coating: Dense and durable, with strong chemical and abrasion resistance, effectively shielding the base from solvents and oils.

- Plastic Coating: Typically polyethylene (PE) or polyvinyl chloride (PVC), providing flexibility, UV resistance, impact protection, and electrical insulation.

Coating Methods

Depending on the process, coated stainless steel cable ties can be finished using several surface treatment methods:

- Powder Coating: Electrostatic application of epoxy powder cured at high temperature to form a dense, durable layer ideal for outdoor exposure.

- Plastic Coating: Molten PVC or PE is extruded over the stainless steel base, forming a seamless thick protective layer with excellent electrical insulation.

- Dipping: The heated metal strip is dipped into PVC fluid to create a uniform, full coating, offering good cost-performance for general corrosion protection.

Specifications

Example specifications of coated stainless steel cable ties(Take 4.6mm width as an example) using powder coating process:

| ITEM NO | Length | Width(mm) | Max.Bundle Dia.(mm) | Min tensile strength | ||

| Inch | mm | lbs | N | |||

| WD-4.6x100CSS | 3.9″ | 100 | 4.6 | 25 | 180 | 800 |

| WD-4.6x150CSS | 5.9″ | 150 | 37 | |||

| WD-4.6x200CSS | 7.9″ | 200 | 50 | |||

| WD-4.6x250CSS | 9.9″ | 250 | 63 | |||

| WD-4.6x300CSS | 11.8″ | 300 | 76 | |||

| WD-4.6x350CSS | 13.8″ | 350 | 89 | |||

| WD-4.6x400CSS | 15.8″ | 400 | 102 | |||

| WD-4.6x450CSS | 17.7″ | 450 | 115 | |||

| WD-4.6x500CSS | 19.7″ | 500 | 128 | |||

| WD-4.6x550CSS | 21.7″ | 550 | 141 | |||

| WD-4.6x600CSS | 23.6″ | 600 | 154 | |||

| WD-4.6x650CSS | 25.6″ | 650 | 167 | |||

| WD-4.6x700CSS | 27.6″ | 700 | 180 | |||

| WD-4.6x750CSS | 29.6″ | 750 | 191 | |||

| WD-4.6x800CSS | 31.5″ | 800 | 193 | |||

| WD-4.6x850CSS | 33.5″ | 850 | 208 | |||

| WD-4.6x900CSS | 35.5″ | 900 | 217 | |||

| WD-4.6x950CSS | 37.4″ | 950 | 231 | |||

| WD-4.6x1000CSS | 39.4″ | 1000 | 243 | |||

Product Features

- Strong Locking: Stainless steel cable ties coated adopt a ball-lock design, providing high tensile strength and resistance to vibration for long-term fastening stability.

- Excellent Corrosion Resistance: Dual protection from stainless steel and coating effectively resists chemicals, salt spray, and humidity for extended service life.

- Electrical Insulation: The continuous coating layer prevents current flow, avoiding short circuits and galvanic corrosion.

- Weather Resistance: Coatings resist UV, temperature changes, and harsh climates, maintaining performance in outdoor and wide-temperature environments.

- Attractive Appearance: The plastic coating gives a smooth, uniform finish for a clean and professional look.

Applications

- Marine and High-Corrosion Environments: Stainless steel cable ties coated are ideal for ships, offshore platforms, and coastal installations, effectively preventing galvanic corrosion caused by salt spray.

- Power and Electrical Installations: Coated cable ties are widely used in power distribution systems and control cabinets, where insulation prevents short circuits and cable wear.

- Chemical and Wastewater Plants: Plastic coated metal cable ties withstand acids, solvents, and humid air for long-term stability in harsh industrial environments.

- Outdoor Public Facilities: PVC coated cable ties are used for fixing fences, signs, and lighting devices, providing UV and weather resistance for long-term durability.

Differences from Regular Stainless Steel Cable Ties

| Comparison Item | Regular Stainless Steel Cable Ties | Coated Stainless Steel Cable Ties |

|---|---|---|

| Surface Treatment | None | Powder, Plastic, or Dip Coating |

| Corrosion Resistance | Moderate | Enhanced for salt, acid, and alkali environments |

| Electrical Insulation | Conductive | Insulated, suitable for electrical use |

| Touch & Appearance | Sharp edges | Smooth and safe to handle |

| Cost | Lower | Higher but with longer lifespan |

FAQ

Q1: Are pvc coated ss cable ties suitable for marine environments?

Yes. For marine conditions, it is recommended to use 316-grade stainless steel with PVC coating or epoxy powder coating. This combination provides long-lasting resistance to seawater and high salt spray.

Q2: Does the surface coating reduce the mechanical strength of pvc coated stainless steel cable ties?

No. The coating acts only as a protective layer and does not affect the mechanical strength. The load capacity of cable tie coated products is fully supported by the stainless steel body.

Q3: Are stainless steel coated cable ties customizable in color and size?

Yes. We offer custom options in various colors and lengths for easy identification and installation in different applications.

Q4: Do stainless steel cable ties coated require special installation tools?

It is recommended to use dedicated installation tools to maintain consistent tension, improve efficiency, and ensure secure fastening quality.

Q5: Compared with uncoated stainless steel cable ties, do plastic coated wire ties change in size?

Powder coating has almost no dimensional change, while pvc coated wire ties become slightly wider and thicker.