1. Introduction

What is spiral wrap for cables? It is a new cable protection and organization solution that replaces traditional metal spring guards. Featuring a spiral structure design, it combines flexible protection, convenient installation, and reusability. It effectively extends cable service life and adapts to multi-scenario cable management needs, making it an ideal cable companion for industrial, household, and electronic fields. But why can spiral wrap for cables outperform traditional protection tools? How should suitable types be selected for different scenarios? And what specific applications can it be used in? Let us explore the answers one by one.

2. Why Choose Spiral Wrap for Cables?

Among numerous cable protection products, spiral wrap for cables stands out due to its multiple irreplaceable advantages, which are also the key reasons it has become a mainstream cable management spiral.

As a professional spiral wrap cable protector, it provides comprehensive protection, effectively resisting cable abrasion, scratching, chemical corrosion, ultraviolet radiation, and high and low temperature impact. It prevents insulation damage, short circuits, and other failures, significantly reducing safety risks and maintenance costs. Compared with one-time-use products such as tapes and heat shrink tubes, spiral wrap for cables features flexible reusability. It is not easily deformed or damaged during disassembly and installation, and can be repeatedly wrapped according to cable layout adjustments, making it both environmentally friendly and cost-effective for long-term use.

Installation convenience is another major highlight—no tools or adhesives are required. Manual wrapping completes installation, and quick disassembly and installation can be achieved without shutdown, greatly improving operation and maintenance efficiency. This is also an important reason why cable spiral wraps are highly favored. At the same time, it is also an efficient spiral cable cord organizer, capable of bundling loose cables neatly to reduce clutter. It also supports multi-color customization (mainly black and white, with customization available on demand), such as white cable spiral wrap or white spiral cable wrap, facilitating cable classification and identification, making the overall layout cleaner and more aesthetically pleasing.

In addition, spiral wrap for cables offers a wide range of material options to adapt to different environmental requirements. Whether for general scenarios or special working conditions, corresponding solutions can be found, which is also why it is more advantageous than ordinary cable protector spiral.

3. What Scenarios Can Spiral Wrap for Cables Be Used In?

Spiral wrap for cables is highly adaptable and covers cable management needs across multiple industries. Different types of spiral cable sleeve can deliver excellent performance in corresponding scenarios:

Industrial machinery field: Hydraulic hoses, pneumatic hoses, and electrical cable protection for equipment such as excavators, loaders, injection molding machines, CNC machine tools, and robotic arms. Plastic spiral cable wrap or cable spiral protector is recommended. These products can resist wear and oil contamination during equipment operation and adapt to bending and vibration under complex working conditions. Among them, cable spiral sleeve models with an I-shaped wall structure offer more outstanding compression and impact resistance.

Automotive and aviation fields: Vehicle wiring harnesses and aviation cable protection need to adapt to dynamic bending scenarios. Electrical cable spiral wrap is an ideal choice. It can resist high temperature and mechanical vibration damage, ensuring line stability. Its excellent elasticity and tensile properties allow it to flexibly follow cable deformation without affecting normal equipment operation.

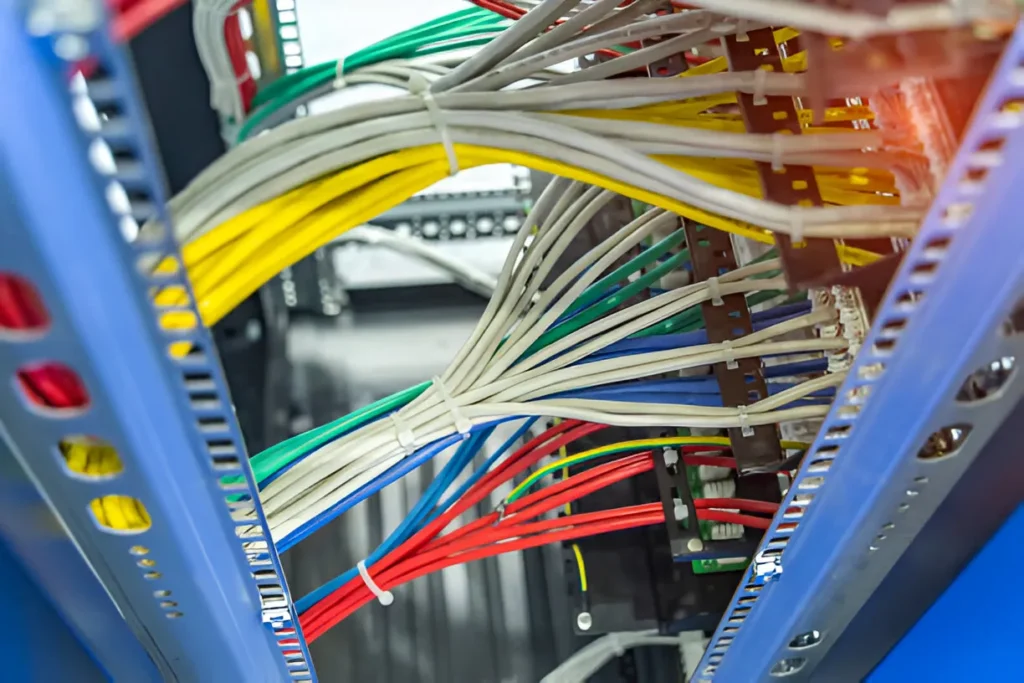

Electronics and IT fields: Cable organization in server rooms, cabinets, office workstations, as well as home audio-visual systems and computer hosts, is suitable for spiral cable wire wrap or cable organizer spiral wrap. For small cable bundles, 4mm spiral cable wrap offers excellent adaptability, effectively preventing cable entanglement and wear, making space layout more orderly.

New energy field: Charging pile wiring harness protection needs to adapt to outdoor high and low temperature and ultraviolet environments. UV-modified PE material spiral sleeve for cable is the preferred choice. It can effectively resist sun and rain erosion and improve the operational safety performance of charging piles.

Other special scenarios: Medical equipment, marine equipment, outdoor engineering cables, etc., can select corresponding materials and specifications according to requirements. For example, PTFE material spiral wrap cable sleeve can be selected for strong corrosive environments, and cable spiral binding can be used in scenarios requiring fixed storage.

4. How to Choose and Install Spiral Wrap for Cables?

To ensure spiral wrap for cables performs at its best, correct selection and installation are critical. Below is a detailed guide:

(1) How to Choose the Right Spiral Wrap for Cables?

Determine material: Choose according to the usage environment—PE material cable spiral wraps with high cost performance for general scenarios; UV-modified PE or nylon materials for outdoor scenarios; PTFE (Teflon) material for high-temperature and strongly corrosive environments; modified PP material for scenarios with prominent wear resistance and compression resistance requirements.

Match specifications: Measure the cable bundle diameter and select a model with an inner diameter 1–2 mm larger than the total cable bundle diameter. This ensures close protection while reserving space for slight cable movement, avoiding extrusion of cable insulation. For example, a 3 mm cable bundle diameter can use 4mm spiral cable wrap; an 8 mm diameter is suitable for φ10 mm specifications. The standard length is 10 m. For special requirements, spiral cable wrap suppliers can be contacted to customize length.

Customization needs: If there are special requirements such as color or flame retardancy, customization services can be selected. For example, when cable type differentiation is required, customizing white spiral cable wrap or other colors makes classification clearer.

(2) How to Properly Install Spiral Wrap for Cables?

Preparation: Confirm that the selected spiral cable wrapping matches the cable bundle specifications. Clean impurities from the cable surface to ensure there is no oil contamination or sharp protrusions.

Wrapping installation: Start from one end of the cable bundle and spiral-wrap the spiral cable sleeve around the cable surface. Adjust tightness to ensure proper fit, avoiding looseness that could cause detachment or excessive tightness that could compress the cable.

Branch handling: If branch cables need to be led out, they can be directly pulled out from the spiral opening without dismantling the overall wrapping structure, maintaining protective integrity. This is also one of the core design advantages of cable organizer spiral.

Adjustment and reuse: When adjusting layout, spiral wrap for cables can be directly stretched, bent, or removed and rewrapped for reuse. Its excellent elasticity and tensile properties ensure stable performance even after repeated use.

5. Customization Services and Frequently Asked Questions

(1) Customization Services

Spiral wrap for cables supports on-demand customization of length, color, and material (flame retardant, UV-resistant, etc.) to meet special scenario requirements. Standard specifications are available from stock. Customized models with specific inner diameters, colors, or materials have a delivery cycle of 5–7 working days. For bulk customization, spiral cable wrap suppliers can be contacted to negotiate shorter lead times.

(2) Frequently Asked Questions (FAQ)

Q: Which material of spiral wrap for cables is more suitable for outdoor use?

A: UV-modified PE or nylon materials are recommended. Both offer excellent UV resistance and high and low temperature resistance, effectively resisting harsh outdoor environmental erosion and extending service life.

Q: Can spiral wrap for cables be reused?

A: Yes. The product is made of highly elastic materials and is not easily deformed or damaged during installation and removal. It can be repeatedly wrapped and reused according to cable layout adjustments, making it environmentally friendly and cost-effective.

Q: How can I confirm whether the thickness of the selected cable spiral sleeve is suitable?

A: The thickness of standard specifications has been optimized according to outer diameter. For example, φ4 mm models have a thickness of 0.5 mm, and φ50 mm models have a thickness of 1.4 mm, meeting the protection needs of corresponding cable specifications. For special working conditions, suppliers can be consulted for customized thickened versions.

6.Conclusion

With comprehensive protection performance, convenient installation methods, and wide application scenarios, spiral wrap for cables has become a preferred solution for cable management. Whether in industrial production, automotive and aviation, home and office, or new energy fields, corresponding spiral cable wrap solutions can be found. If further product details or customization services are required, professional spiral cable wrap suppliers can be contacted to obtain dedicated cable protection solutions.