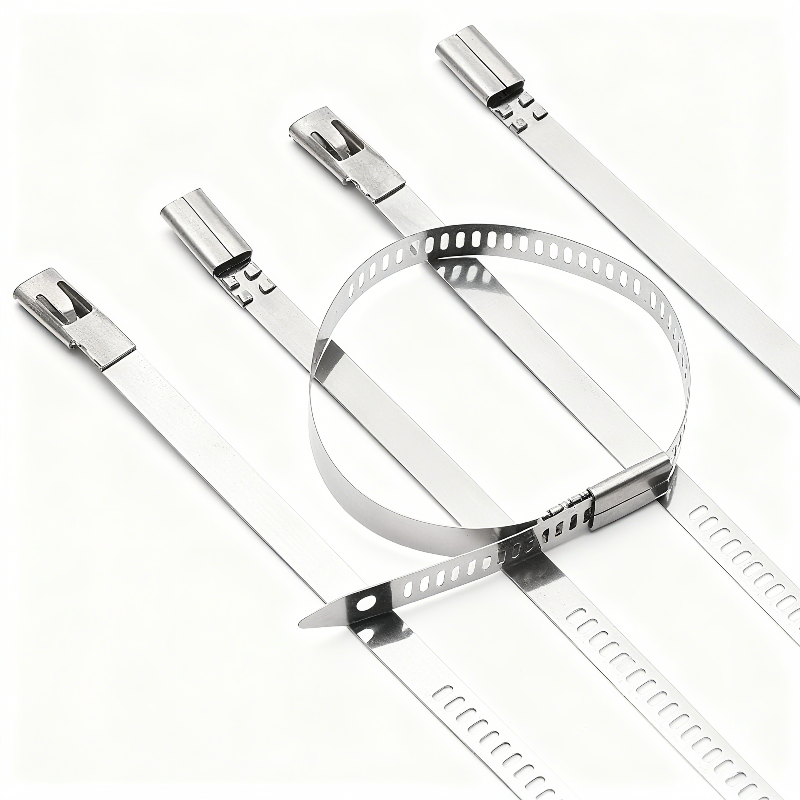

Product Overview

Stainless steel ladder cable ties adopt a high-strength strip substrate combined with a ladder-shaped tooth groove design, forming an industrial-grade fastening solution. The unique step-tooth structure provides anti-reversal locking after tightening, ensuring long-lasting clamping force and excellent vibration resistance. Even under extreme temperatures and corrosive environments, the tie maintains structural integrity, making it ideal for energy transmission, communication infrastructure, petrochemical, and transportation equipment—especially where high temperature or chemical resistance is required and plastic ties cannot perform effectively.

Material Description

| stainless steel ladder cable ties Material | Features & Applications |

|---|---|

| 201 Stainless Steel | Lower nickel content, high hardness and strength, suitable for general industrial and indoor use, offering high cost performance. |

| 304 Stainless Steel | Universal stainless steel with good oxidation and corrosion resistance, suitable for most outdoor and industrial environments. |

| 316 Stainless Steel | Contains molybdenum, excellent performance in high humidity, salt spray, or chemically corrosive environments, commonly used in marine, chemical, and coastal facilities. |

Structure and Working Principle

The working mechanism of stainless steel ladder cable ties is a highly efficient dynamic locking process. The ladder-shaped grooves on the strap work in conjunction with a spring pawl inside the locking head. When the strap is inserted, the pawl slides over the sloped surface of the groove; under tension, any backward movement causes the pawl to instantly engage with the vertical surface of the groove, achieving a secure lock. This “one-way engagement” principle is the key to its superior anti-vibration and anti-loosening performance.

Stainless Steel Ladder Cable Ties Size Table

Below is a partial size chart for stainless steel ladder cable ties. The complete chart can be downloaded from this page.

| ITEM NO | Length | Width (mm) | Max. Bundle Dia. (mm) | Min. Tensile Strength | ||

|---|---|---|---|---|---|---|

| WD-4.5x100SL | 3.9″ | 100 | 4.5 | 25 | 100 lbs | 450 N |

| WD-4.5x150SL | 5.9″ | 150 | 4.5 | 37 | 100 lbs | 450 N |

| WD-4.5x200SL | 7.9″ | 200 | 4.5 | 50 | 100 lbs | 450 N |

| WD-7x300SL | 11.8″ | 300 | 7 | 76 | 155 lbs | 700 N |

| WD-10x500SL | 19.7″ | 500 | 10 | 128 | 225 lbs | 1000 N |

| WD-10x1300SL | 51.2″ | 1300 | 10 | 318 | 225 lbs | 1000 N |

Application Fields

1. Marine and Offshore Engineering

Used for fixing pipelines and cables in ship engine rooms and deck areas. The anti-vibration design of stainless steel ladder ties withstands continuous engine vibration and wave impact. The stainless steel material ensures long-term corrosion resistance in harsh salt spray environments.

2. Rail Transit Systems

Widely used for cable and pipeline bundling under high-speed rail and subway vehicles. The locking mechanism of ladder cable ties effectively resists impact from rail joints and operational vibrations, ensuring safe and reliable fixation throughout the train’s lifespan.

3. Energy and Power Facilities

Used to secure critical pipelines around turbines, compressors, and vibrating equipment in power plants. Ladder style cable ties can withstand the high-frequency vibrations produced by heavy rotating machinery, reducing the risk of downtime caused by loosening.

4. Heavy Engineering Machinery

Provides reliable cable and hose management for excavators, mining trucks, and other equipment. Ladder type cable ties can endure extreme vibrations and shocks during field operations, protecting hydraulic and electrical lines from wear or breakage.

5. Building Seismic Reinforcement

As part of seismic reinforcement systems, they are used to fix pipelines, cable trays, and ducts. During earthquakes, ladder zip ties prevent non-structural components from loosening or falling, improving building safety and reducing secondary hazards.

6. Aerospace Industry

Applied in aircraft interiors to securely fasten wiring harnesses and pipelines. The vibration resistance of stainless steel ladder ties meets the stringent requirements of aviation applications, maintaining absolute connection reliability under intense flight vibration and pressure changes.

Comparison with Stainless Steel Ball Lock Cable Ties

| Item | stainless steel ladder cable ties | ball lock stainless steel cable tie |

|---|---|---|

| Locking Structure | Ladder teeth + pawl engagement | Steel ball wedges in tapered cavity |

| Locking Principle | Multi-point gear engagement | Self-locking ball mechanism, irreversible after locking |

| Appearance | Visible ladder grooves, flat head | Smooth strap, solid head |

| Tensile Strength | High strength | Extremely high tensile strength, wider locking contact |

| Applications | High-vibration environments (wind, petrochemical, railway) | General industry, cabinets, cable trays, power assembly |

| Cost | Slightly higher | Lower cost, better value |

| Installation | Manual or with stainless steel cable tie tool | Recommended to use ss cable tie gun |

Selection Tips:

If pursuing high tensile strength and cost-effectiveness → choose ball lock ss cable ties.

If requiring extreme stability and vibration resistance → choose metal ladder cable ties.

FAQ – Frequently Asked Questions

Q1: Can stainless steel ladder cable ties be used in marine environments?

A1: Yes, but it is recommended to use 316 stainless steel material to improve salt spray resistance.

Q2: What is the main difference between Stainless steel ladder ties and ball lock stainless steel cable tie?

A2: For vibration resistance, choose ladder cable ties; for higher tensile strength, select ball lock cable ties.

Q3: Can Metal ladder zip ties be reopened after locking?

A3: No, they use a one-way locking structure and must be cut to remove.