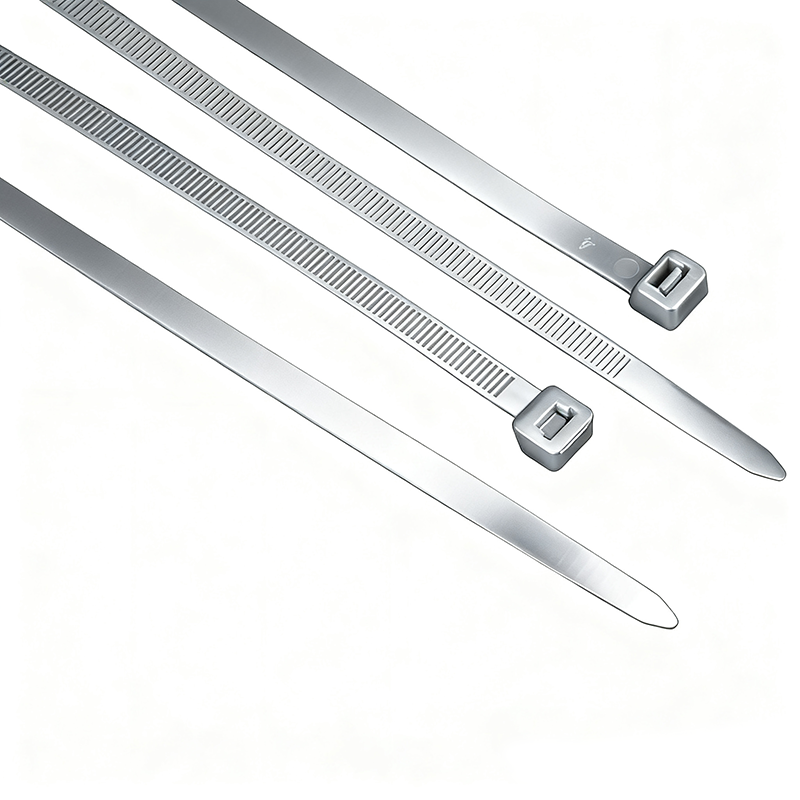

What is silver zip ties

silver zip ties, also known as silver cable ties, have a modern, clean, high-tech visual character and look more professional and refined than traditional black or white wire ties. Silver is a neutral color that pairs well with most colors, especially metal gray, white, and black, and integrates perfectly with contemporary industrial design languages without appearing out of place.

Material Description

Nylon 6 (Nylon 6)

- Hygroscopic Properties: Easily absorbs moisture, which affects its load-bearing capacity in humid environments.

- Tensile Strength: Moderate, suitable for most indoor bundling applications.

- Flame Rating: UL94 V-2.

- Operating Temperature Range: –10°C to 75°C.

- Most Common Application: Home and office cable management.

Nylon 6.6 (PA66)

- Hygroscopic Properties: Low moisture absorption, maintaining strength in humid conditions.

- Tensile Strength: High strength, suitable for carrying heavy loads.

- Flame Rating: UL94 V-2.

- Operating Temperature Range: –20°C to 85°C.

- Aging/UV Resistance: Excellent, reliable for long-term outdoor use.

- Most Common Applications: Outdoor construction, power plants, and aviation equipment.

Polypropylene (PP)

- Hygroscopic Properties: Non-hygroscopic; humidity does not impair its performance.

- Tensile Strength: Lower than nylon but stable, ideal for lightweight bundling.

- Flame Rating: UL94 HB.

- Operating Temperature Range: 0°C to 85°C.

- Chemical Resistance: Excellent; resistant to oils, acids, and alkalis.

- Most Common Applications: Chemical sites and corrosive environments.

Product Features

By relying on the tooth geometry angle and the elastic deformation of the pawl, tensile force is synchronously converted into mechanical locking. When you choose silver zip ties, the core driving factor is visual demand rather than purely performance. If you pursue aesthetics, a sense of technology, and visual coordination, silver is the preferred option. It is used to elevate product grade and make the appearance cleaner and more unified.

Color Matching Process

To accurately confirm the silver color, we recommend sending a physical sample — this is the most reliable method. Of course, you can also choose your desired color via the Pantone color finder. Confirming color from a photo alone may introduce deviation. After confirming the color code, we will thoroughly blend the silver masterbatch with the raw material to ensure the color of the finished silver zip ties is stable and uniform.

Application Scenarios

High-end internal and display scenarios

silver zip ties are used inside and in displays of high-end audio equipment, servers, and similar products. Their metallic feel integrates with aluminum-magnesium alloys and other metals, replacing obtrusive black tie wraps and presenting a neat, professional premium look that significantly enhances overall product feel and brand image.

Devices with light or metallic exteriors

When a device has a white or metallic exterior, black tie wraps can appear like an unsightly patch. silver cable ties can blend perfectly with light-colored bodies to achieve visually “invisible” fixing and maintain appearance harmony; they are commonly used for cable management in appliances, chassis, and furniture.

Outdoor locations that require both performance and aesthetics

For outdoor LED screens, landscape lighting, and similar scenarios, silver cable ties offer good weather resistance while matching metal accessories more closely; they are less visually intrusive than industrial black tie wraps and fit modern architectural and landscape design aesthetics.

Industrial equipment bundling

Server rooms, distribution cabinets, and machinery are mostly made of metal. silver cable ties match metal finishes better and do not look out of place — they are tidy and visually pleasing.

Specifications and Technical Parameters

The size of silver cable ties is determined by three parameters: width, thickness, and length. Generally, width and thickness are proportional to tensile strength, while length determines the maximum bundle diameter that can be accommodated. Below are technical data for a selection of cable ties silver made from Nylon 66.

| Type | Length | Width (mm) | Max. Bundle Dia. (mm) | Min Tensile Strength |

|---|---|---|---|---|

| WD-5×500 | 19.96″ | 4.8 | 150 | 50 lbs / 22 Kgs |

| WD-8×500 | 20″ | 7.6 | 150 | 100 lbs / 45 Kgs |

| WD-10×500 | 20″ | 9 | 150 | 175 lbs / 75 Kgs |

Frequently Asked Questions (FAQ)

What is the difference between cable ties silver and ordinary black or white wire ties?

cable ties silver are closer to a metallic color than ordinary black or white wire ties and are especially suitable for bundling and decorating metal objects. For example, in high-end electronic equipment and automotive modification, using them makes the overall appearance more coordinated.

Can silver tie wraps be used for labeling or classification?

Yes. silver wire ties can serve as visually distinctive markers to help users quickly differentiate cables for different purposes or areas.

Are cable ties silver suitable for outdoor use?

Not necessarily. Ordinary Nylon 6 material is only suitable for indoor use. Only Nylon 66 material that has been compounded with UV stabilizers and heat stabilizers is suitable for outdoor use.