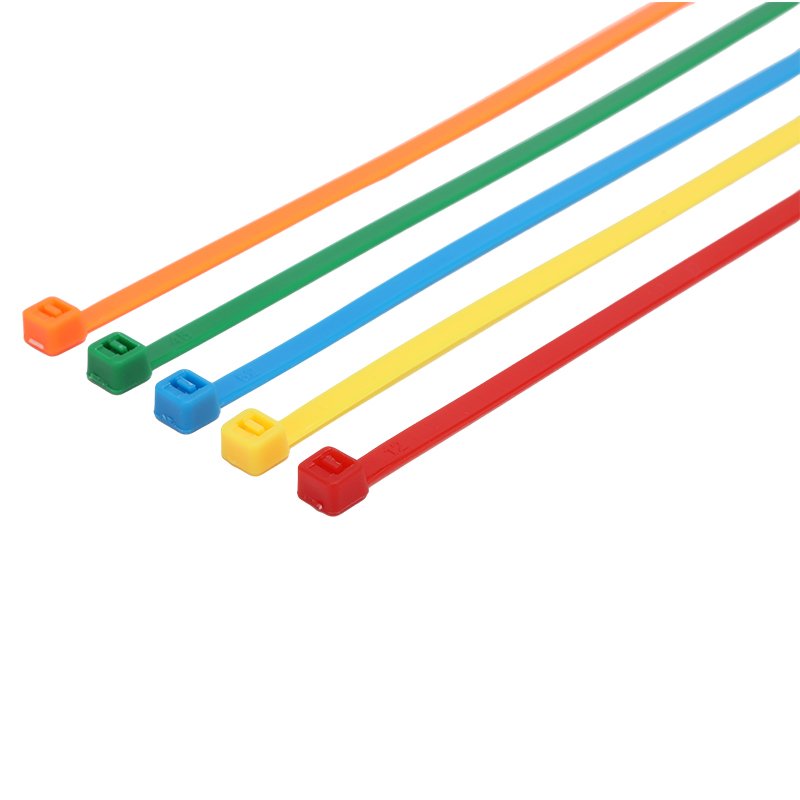

What is Coloured Cable Ties

Colored cable ties are a type of bundling tool that adds multiple color options based on ordinary nylon cable ties. They not only retain the convenient self-locking design for quick fastening but also use different colors to achieve clear visual classification. This kind of color cable ties are often used in wire management, equipment bundling, and item identification. Compared with common black or white cable ties, using colors helps users identify and categorize more quickly, improving operation efficiency and intuitive site management.

Advantages of Multi Color Cable Ties

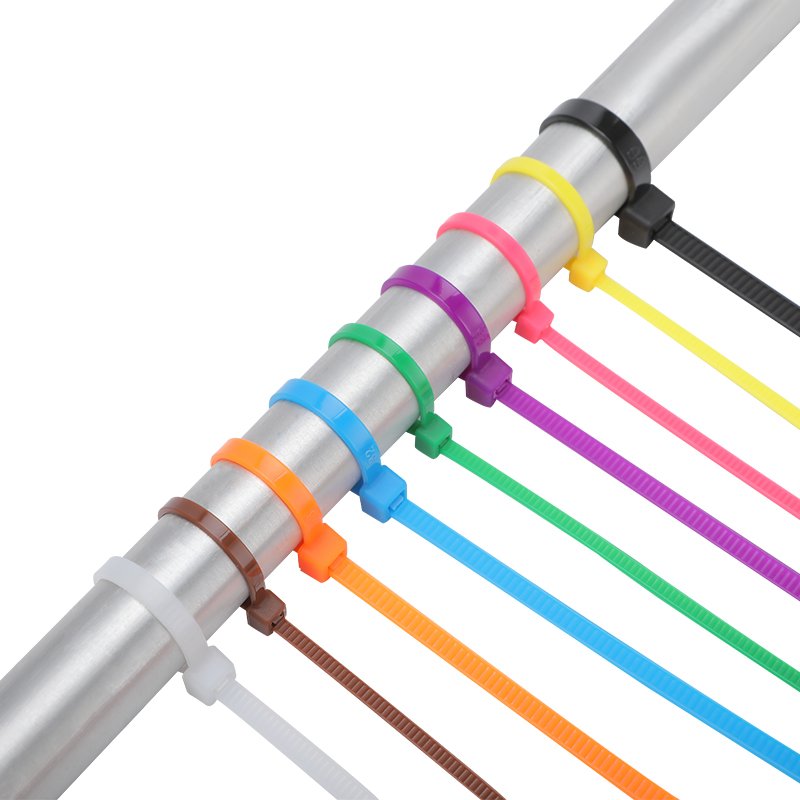

The greatest advantage of colored cable ties lies in their color identification and classification function. Different colors correspond to different purposes, helping users better manage and mark:

- Red: Used for danger warnings and key circuits, visually striking, improving safety recognition.

- Yellow: Suitable for temporary marking and medical waste bundling, bright and easy to distinguish.

- Blue: Often used for network and communication lines, calm appearance, suitable for weak current systems.

- Green: Represents safety and environmental protection, commonly used for grounding wires and outdoor lighting.

- White: Simple appearance, less interference, suitable for home use and places with higher aesthetic requirements.

- Black: Weather-resistant and UV-resistant, widely used in outdoor industrial environments, durable and not easily dirty.

- Pink: High recognition, often used in beauty equipment, female-oriented scenes, or themed decorations.

- Orange: Medium warning color, suitable for construction areas and test circuits requiring special attention.

- Purple: Special identification, used for VIP lines, audio-video equipment, and important channels.

- Brown: Low-key and natural, suitable for gardening, agriculture, and outdoor wooden environments.

- Silver: Strong metallic texture, dirt-resistant, often used in industrial machinery and exhibition display scenarios.

- Gold: Strong decorative effect, often used in high-end equipment displays and brand visual enhancement.

Technical Parameters

Structure Overview

colored cable ties head: designed with a ratchet structure to form a self-locking function, during use the strap body passes through and locks automatically, ensuring easy operation and reliable connection.

Strap body: surface pressed with uniform teeth, effectively increasing friction, preventing loosening or slipping after bundling, ensuring that fixed objects remain stable for a long time.

Material Options

- Nylon 6: Provides good overall performance and cost-effectiveness, ideal for most indoor environments, suitable for daily fixing and cable management.

- Nylon 66 UV-resistant: Based on Nylon 66 with enhanced UV resistance, more suitable for long-term outdoor use, effectively delaying aging caused by sunlight.

- Nylon 66 with Metal Powder: Contains metal powder and can be detected by specific equipment, suitable for industries with strict foreign object control such as food and pharmaceuticals.

- Nylon 66 V0 Flame Retardant: Difficult to ignite and self-extinguishes quickly, commonly used in electrical cabinets or equipment with clear fire safety requirements.

- Polypropylene: Excellent chemical resistance, especially suitable for chemical, water treatment, or pharmaceutical environments with corrosive substances.

Size Selection

When selecting cable tie sizes, both the maximum diameter of the object to be bundled and the tensile strength required in the application should be considered. Cable tie lengths range from about 100mm to 1500mm, widths usually from 2.5mm to 12mm, to fit different bundling scales. Tensile strength covers approximately 8kg to 100kg, and users need to choose the appropriate specifications according to actual force conditions to ensure safe use. Below is our company’s colored cable ties size chart.

| Type | Length (inch/mm) | Width (mm) | Max. Bundle Dia. (mm) | Min. Tensile Strength |

|---|---|---|---|---|

| WD-3×100 | 4″ / 100 | 2.5 | 22 | 8kg |

| WD-3×150 | 6″ / 150 | 2.5 | 35 | 8kg |

| WD-3×200 | 8″ / 200 | 2.5 | 50 | 8kg |

| WD-4×100 | 4″ / 100 | 3.6 | 22 | 18kg |

| WD-4×150 | 6″ / 150 | 3.6 | 35 | 18kg |

| WD-4×200 | 8″ / 200 | 3.6 | 50 | 18kg |

| WD-4×250 | 10″ / 250 | 3.6 | 65 | 18kg |

| WD-4×300 | 12″ / 300 | 3.6 | 80 | 18kg |

| WD-4×350 | 13.8″ / 350 | 3.6 | 90 | 18kg |

| WD-4×400 | 16″ / 400 | 3.6 | 110 | 18kg |

| WD-5×150 | 6″ / 150 | 4.8 | 35 | 22kg |

| WD-5×200 | 8″ / 200 | 4.8 | 50 | 22kg |

| WD-5×250 | 10″ / 250 | 4.8 | 65 | 22kg |

| WD-5×300 | 12″ / 300 | 4.8 | 82 | 22kg |

| WD-5×350 | 14″ / 350 | 4.8 | 90 | 22kg |

| WD-5×400 | 16″ / 400 | 4.8 | 105 | 22kg |

| WD-5×450 | 17.7″ / 450 | 4.8 | 125 | 22kg |

| WD-5×500 | 19.96″ / 500 | 4.8 | 150 | 22kg |

| WD-8×200 | 8″ / 200 | 7.6 | 50 | 45kg |

| WD-8×250 | 10″ / 250 | 7.6 | 65 | 45kg |

| WD-8×300 | 12″ / 300 | 7.6 | 82 | 45kg |

| WD-8×350 | 15″ / 350 | 7.6 | 90 | 45kg |

| WD-8×400 | 16″ / 400 | 7.6 | 105 | 45kg |

| WD-8×450 | 18″ / 450 | 7.6 | 118 | 45kg |

| WD-8×500 | 20″ / 500 | 7.6 | 150 | 45kg |

| WD-8×550 | 21.6″ / 550 | 7.6 | 165 | 45kg |

| WD-8×600 | 23.6″ / 600 | 7.6 | 180 | 45kg |

| WD-10×400 | 16″ / 400 | 9 | 105 | 75kg |

| WD-10×450 | 18″ / 450 | 9 | 130 | 75kg |

| WD-10×500 | 20″ / 500 | 9 | 150 | 75kg |

| WD-10×550 | 21.6″ / 550 | 9 | 165 | 75kg |

| WD-10×600 | 23.6″ / 600 | 9 | 165 | 75kg |

| WD-10×650 | 25.6″ / 650 | 9 | 165 | 75kg |

| WD-10×700 | 28″ / 700 | 9 | 175 | 75kg |

| WD-10×720 | 28.3″ / 720 | 9 | 180 | 75kg |

| WD-10×760 | 29.5″ / 760 | 9 | 220 | 75kg |

| WD-10×800 | 31.5″ / 800 | 9 | 180 | 75kg |

| WD-10×850 | 34.7″ / 850 | 9 | 230 | 75kg |

| WD-10×900 | 35.5″ / 900 | 9 | 265 | 75kg |

| WD-10×1020 | 40.2″ / 1020 | 9 | 295 | 75kg |

| WD-10×1200 | 48″ / 1200 | 9 | 345 | 75kg |

| WD-12×400 | 16″ / 400 | 12 | 105 | 100kg |

Applications

Coloured cable ties are made into different colors according to the color card provided by customers, commonly used for binding and fixing distribution boxes and cabinets as warning signs, for classifying and fixing different kinds of fruits and vegetables as well as classifying and managing goods.

Circuit classification: Different colored cable ties are used to distinguish power lines, signal lines, and ground lines, e.g., red zip ties represent fire lines and blue zip ties represent zero lines.

Fiber classification: In telecom base stations, different colors are used to identify the transmission direction or purpose of the fiber (e.g. uplink/downlink). Blue cable ties correspond to uplink signal lines, orange zip ties correspond to downlink signal lines, and yellow zip ties correspond to redundant backup link lines. Distinguish according to signal type and network level: green zip ties for single-mode fiber optic cables, gray cable ties for multi-mode fiber optic cables, purple zip ties for dedicated control channel cables, and black cable ties for encrypted transmission channel cables.

Classification of power system: Use yellow cable ties to distinguish 110V and red cable ties to distinguish 220V, so as to ensure the safety of power consumption.

Piping and equipment marking: In chemical plants, purple cable ties are generally used to mark chemical piping, and green cable ties are used to mark the cooling water system, so as to make a clear distinction and increase safety. In the electrical industry, color-coded sensors are matched to different types of sensors for quick location, such as yellow cable ties for safety circuits in industrial robots.

Data center management: color-coding network tiers (e.g. blue cable ties for Gigabit networks, yellow cable ties for 10G networks) or cables by customer (e.g. red cable ties for VIP customer lines).

Temporary structural reinforcement and wedding themed arrangements: Outdoor music festivals use black or green cable ties to secure tents and billboards, hidden and solid. Weddings use gold or silver zip ties to fix floral arrangements or lights, both functional and beautiful.

Wiring harness management: In automotive repair, red cable ties mark modified wiring and black cable ties are used for original wiring; blue cable ties are used in boats to differentiate seawater system wiring.

Safety warnings and inspections: Orange cable ties are used to enhance the visibility of warning signs in maintenance areas or hazardous locations. After the security check has been passed, use a green cable tie, for example, to mark items that have passed the security check and to avoid repetitive operations.

Plant support and bundling: Use green or brown zip ties to secure vines or simulated plants to achieve color consistency and increase ornamental value.

Storage and organization: Use colors to classify charging cables in the study (e.g. red cable ties for cell phone charging cables, blue cable ties for tablet charging cables).

Emergency marking: For disaster relief, use red cable ties to mark areas to be prioritized, and yellow cable ties to represent areas that have been cleared.

Medical equipment: When temporarily fixing medical pipelines, differentiate oxygen, suction device and other functions by color. Generally, white cable ties are used for oxygen piping and yellow cable ties are used for suction piping. If mixed gases are involved (e.g., O₂/CO₂),

FAQ

Q1: What is the tensile strength of zip tie colors?

A1: Different sizes and widths of cable ties have different tensile strengths, generally ranging from 8kg to 100kg. Please refer to the technical parameters when selecting.

Q2: Are colored tie wraps suitable for outdoor use?

A2: Ordinary types are not suitable for long-term outdoor use. For weather resistance, choose Nylon 66 UV-resistant material.

Q3: Can cable tie color be reused?

A3: Ordinary self-locking cable ties cannot be reused. If multiple bindings are required, choose releasable or reusable cable ties.

Q4: Can color cable ties be customized with colors or printing?

A4: With minimum order quantities met, various colors or printing can be customized.