1. Product Overview

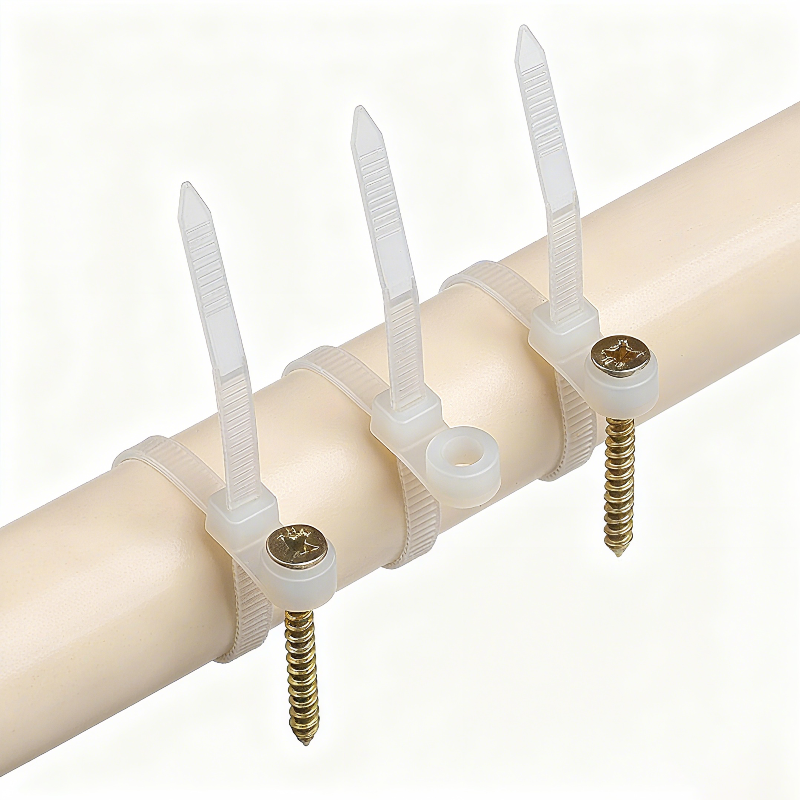

Cable ties with Screw Hole are an efficient solution that combines cable bundling and mounting functions. Compared with traditional cable ties, their uniqueness lies in the head design, which includes a screw mounting hole. This allows the wire bundle to be directly fixed onto walls, panels, or equipment surfaces using screws. This design not only enhances the stability and neatness of cable routing but also simplifies installation. It is particularly suitable for electrical installations, mechanical assemblies, automotive applications, and other fields requiring reliable cable management.

2. Difference Between Cable Ties with Screw Hole and Standard Self-locking Cable Ties

Standard Self-locking Cable Ties

The structure mainly consists of a strap and a one-way locking head. During installation, the tail end passes through the locking head and is tightened by the internal ratchet structure. Its fixation relies entirely on the bundling force of the tie itself. To secure the bundle to a surface, additional accessories such as cable tie mounts or clips are required.

Cable Ties with Screw Hole

They have a key improvement based on the traditional locking head:

- Integrated Mounting Head: The locking head is designed as a widened and thickened platform with a pre-molded standard screw hole.

- Built-in Fixing Function: This screw hole allows you to use a screw to fasten the zip ties with screw hole directly to walls, cabinets, metal plates, or any structure with a threaded hole.

Summary of Key Differences:

In short, standard cable ties can only “bundle,” while screw hole zip ties integrate both “bundling and mounting” in one part. This all-in-one design eliminates the need for extra accessories and provides a more direct and stable installation solution.

3. Material Analysis

The standard materials of Cable Ties with Screw Hole are generally Nylon 6 or Nylon 66, each with distinct performance characteristics. The table below shows the main differences:

| Property | Nylon 66 (PA66) | Nylon 6 (PA6) |

|---|---|---|

| Tensile Strength | Higher, stronger | Slightly lower but sufficient |

| Toughness | More rigid and brittle | Better flexibility |

| Melting Point | Approx. 260°C, good short-term heat resistance | Approx. 220°C |

| Water Absorption | 2.5%, more stable tensile strength | 3.5%, reduced tensile strength when wet |

| Outdoor UV Resistance | Average, UV stabilizer required | Weaker, UV stabilizer required |

| Cost | Higher, with stricter process requirements | Lower, more cost-effective |

How to Choose the Right Material

Prefer Nylon 66 (PA66) when: Strength, heat resistance, and stability in humid environments are required. Ideal for engine compartments, industrial equipment, and vibration-prone areas.

Prefer Nylon 6 (PA6) when: Budget-sensitive applications need good flexibility for bending or impact resistance. Common in indoor cabinets, home appliances, and light-duty wire bundling.

Outdoor Long-Term Use: Regardless of material, outdoor cable ties with screw holes should include UV stabilizers and be labeled as “UV Resistant” or “Weather Resistant.”

4. Specifications and Dimensions

Cable ties with screw hole are available in various sizes from 3.6×100mm to 7.6×380mm, meeting different bundle diameter needs. Each model comes with a corresponding screw hole size and tensile strength.

| Type | Length (Inch) | Length (mm) | Width (mm) | Max. Bundle Dia. (mm) | Screw Hole Dia. (mm) | Min. Tensile Strength (lbs) | Min. Tensile Strength (Kgs) |

|---|---|---|---|---|---|---|---|

| WD-4x100SH | 4″ | 100 | 3.6 | 22 | 4.8 | 40 | 18 |

| WD-4x150SH | 6″ | 150 | 3.6 | 35 | 4.8 | 40 | 18 |

| WD-4x200SH | 8″ | 200 | 3.6 | 50 | 4.8 | 40 | 18 |

| WD-5x200SH | 8″ | 200 | 4.8 | 50 | 5.2 | 50 | 22 |

| WD-5x300SH | 12″ | 300 | 4.8 | 82 | 5.2 | 50 | 22 |

| WD-5x400SH | 16″ | 400 | 4.8 | 105 | 5.2 | 50 | 22 |

| WD-8x300SH | 12″ | 300 | 7.6 | 82 | 7.0 | 100 | 45 |

| WD-8x380SH | 14.6″ | 380 | 7.6 | 102 | 7.0 | 100 | 45 |

5. Installation and Applications

Installation Steps

- Position and Drill: Mark the screw hole position on the surface (panel, wall, or bracket) and drill a matching hole.

- Fix the Head: Insert a screw through the hole of the wire ties with screw hole head and tighten it firmly in place.

- Bundle Cables: Wrap the strap around the cables and pass the tail through the self-locking head.

- Tighten and Finish: Pull tight to secure the bundle, then trim off any excess strap length.

Application Scenarios

- Electrical Cabinets and Control Panels: Mount bundles directly to side plates or rails for organized wiring.

- Machinery and Equipment: Secure cables or hoses to metal frames, even in vibration environments.

- Automotive and Transport: Ideal for high-temperature, vibration-resistant cable management near engines or chassis.

- Outdoor Installations: When using UV-resistant ties, cables can be directly fastened to fences, towers, or exterior walls.

6. Product Advantages

- Stronger Fixation: Combining screw mounting with a self-locking structure provides dual stability. Screws keep the screw zip ties firmly attached to the surface, resisting vibration and displacement, while the self-lock ensures tight bundling.

- Integrated Design: The all-in-one structure removes the need for extra mounts. Simply screw the zip tie in place to complete both bundling and positioning in one step, improving efficiency and inventory management.

- Professional Wiring: Direct mounting prevents sagging and swinging, maintaining a tidy appearance and reducing wear from friction, ensuring long-term reliability and aesthetics.

7. FAQ

Q1: Can Screw Cable Ties be reused?

A1: Standard Cable Ties with Screw Hole are one-time self-locking structures and cannot be reused once cut.

Q2: Can screw hole cable ties be used outdoors for a long time?

A2: Yes. When made from UV-resistant Nylon 66, they can withstand sunlight, moisture, and rain for 1–3 years. Regular nylon models are better suited for indoor or temporary applications.

Q3: What is the difference between Tie Wraps with Screw Hole and standard nylon tie wraps?

A3: The main difference lies in the mounting method: standard cable ties rely solely on self-locking for bundling, while Cable Ties with Screw Holes combine “bundling + positioning” using screws, providing superior vibration and slip resistance.