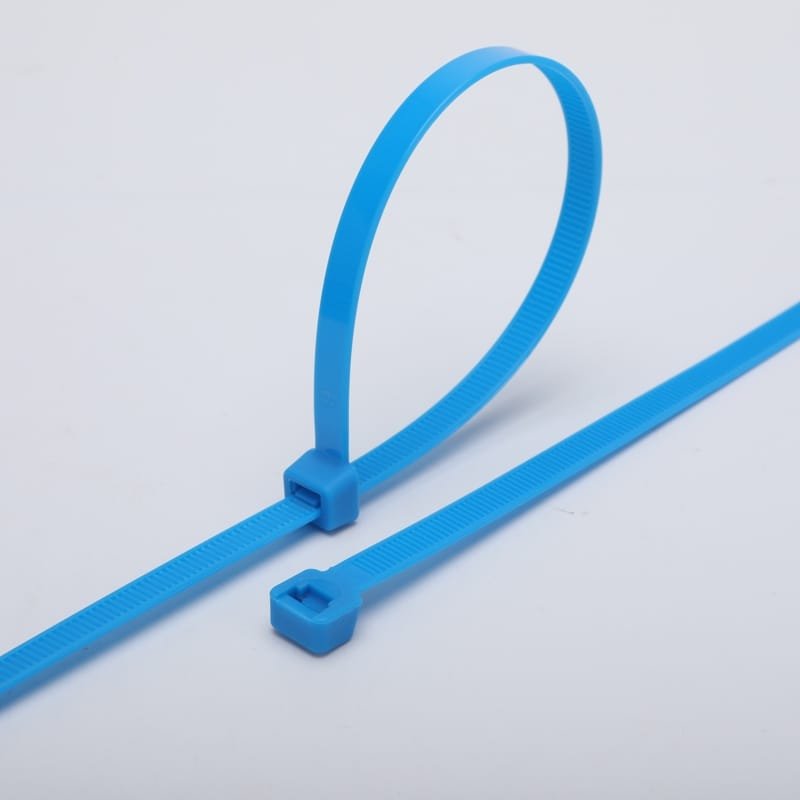

What are blue zip ties?

Blue is a relatively cool and subdued color in the color spectrum, with lower sensitivity than red and green. Blue zip ties convey a calm and professional impression and are often used for color-coding management of networks, data cables, and pipelines carrying cold water or low-temperature media, helping maintenance personnel quickly identify and organize them.

1. Material Specifications

Nylon 6 (Nylon 6)

– Moisture content: High, which may affect its load-bearing capacity in high-humidity environments.

– Tensile strength: Medium strength, suitable for everyday indoor bundling.

– Flame retardant standard: UL94 V-2.

– Operating range: –10 °C to 75 °C.

– Recommended use: Home wiring and office cable fixation.

Nylon 6.6 (PA66)

– Moisture content: Low moisture absorption, more stable performance.

– Tensile strength: High strength, suitable for applications with heavy loads.

– Flame retardant standard: UL94 V-2.

– Operating range: –20 °C to 85 °C.

– UV resistance: Excellent, suitable for prolonged outdoor exposure.

– Recommended applications: Building exteriors, electrical wiring, aviation, and harsh environments.

Polypropylene (PP)

– Moisture absorption: Non-absorbent, humidity does not affect performance.

– Tensile strength: Lower than nylon series but stable performance, suitable for lightweight bundling.

– Flame retardant standard: UL94 HB.

– Operating range: 0 °C to 85 °C.

– Chemical stability: Highly resistant to acids, alkalis, and oils.

– Recommended applications: Corrosive environments such as chemical plants and production lines.

2. Product Features

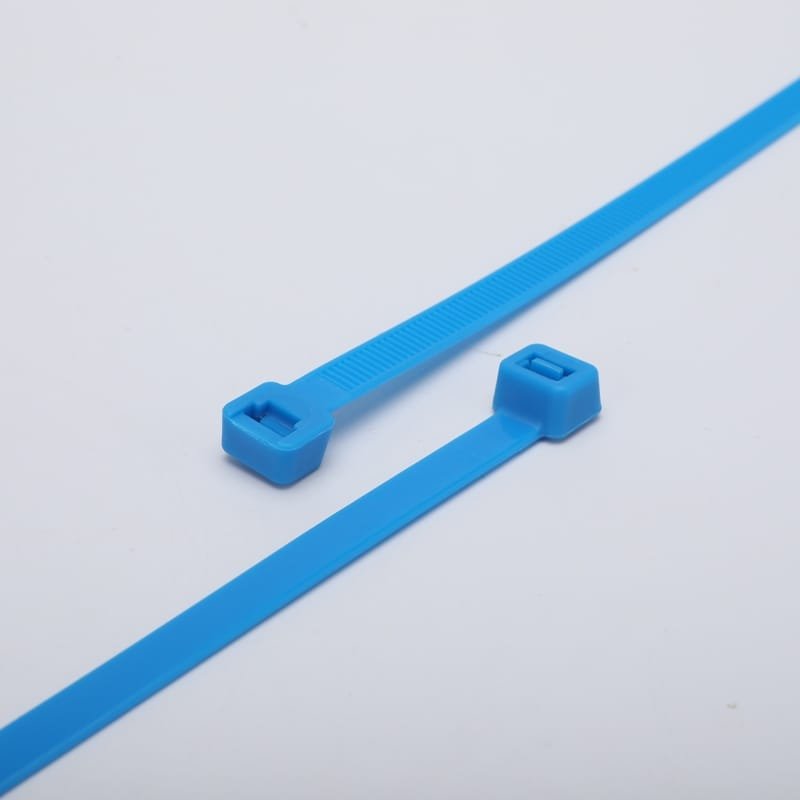

The elastic plastic locking tongue precisely engages with the inclined teeth on the strap body, forming a ratchet-style self-locking system to prevent loosening due to vibration after bundling. In the aviation industry, cable ties blue are commonly used to secure wiring harnesses in aircraft main wheel wells. In everyday industrial applications, they are used to bundle network and data cables for classification and management.

3. Color Selection Process

You can send us samples of blue tie wraps , which is the most accurate method to determine the blue color code. You can also select the desired color using the Pantone Color Chart. Referring to photos alone may result in some color differences. After confirming the color code, we will mix the corresponding blue color masterbatch into the raw material to ensure consistent color across all blue zip ties.

4. Application Scenarios for Blue Zip Ties

Data Centers, Network Cabling

Used to distinguish between Cat5e, Cat6 patch cables, fiber optic patch cables, or group them by purpose or floor to reduce troubleshooting time.

Electrical Distribution, Control Cabinets

Used to identify control circuits or signal lines for maintenance and fault localization.

Construction, HVAC

Used as an identification color for cold water or low-temperature medium pipelines (a common practice, not a mandatory standard).

Medical and laboratory settings

Color-coding cables and pipes by equipment or reagent category (must follow institutional procedures)

Logistics and warehousing

Unify color-coded bundling for specific types of goods or inventory to facilitate inventory counting and identification.

5. Specifications and technical parameters

The specifications of cable ties blue are determined by three parameters: width, length, and thickness. The larger the width and thickness, the stronger the tensile strength; the longer the length, the larger the diameter of the cable bundle that can be secured. Taking nylon 66 material as an example, the following are the technical parameters of some of blue wire ties.

cable ties sizes

| Type | Length | Width(mm) | Max.Bundle Dia.(mm) | Min tensile strength | |||||||||

| Inch | mm | lbs | Kgs | ||||||||||

| WD-3×200 | 8″ | 200 | 2.5 | 50 | 18 | 8 | |||||||

| WD-4×200 | 8” | 200 | 3.6 | 50 | 40 | 18 | |||||||

| WD-5×200 | 8″ | 200 | 4.8 | 50 | 50 | 22 | |||||||

| WD-8×200 | 8″ | 200 | 7.6 | 50 | 100 | 45 | |||||||

6. Frequently Asked Questions (FAQ)

Q1: How many colors are available for blue zip tie?

A1: Generally, as long as the minimum order quantity is met, various shades of blue (e.g., light blue cable ties) can be customized.

Q2: Can I apply my own brand label to the outer packaging?

A2: Our factory supports OEM and ODM. As long as the minimum order quantity is met, custom labels, hang tags, or printed pattern packaging bags can be customized.

Q3: Do blue zip ties have metal-detectable properties?

A3: This product is a standard plastic blue cable tie made without metal powder, so it does not have metal-detectable properties. You can search for “blue metal detectable cable ties” on our website or contact us for more information.