Uses for color cable ties

Have you ever used cable ties at home or in the workpla […]

阅读更多

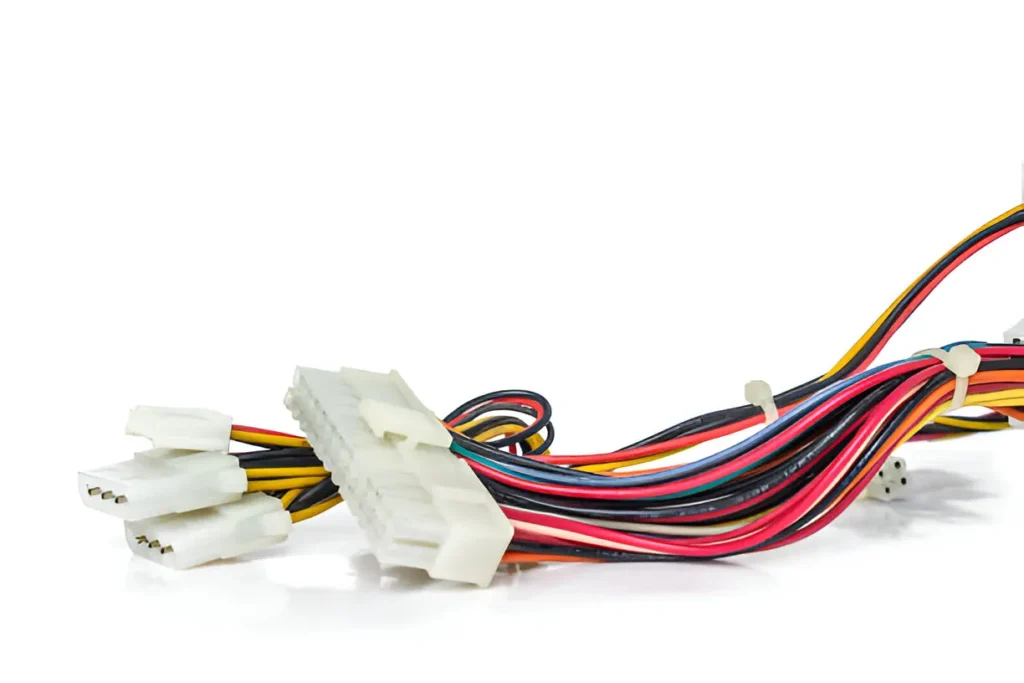

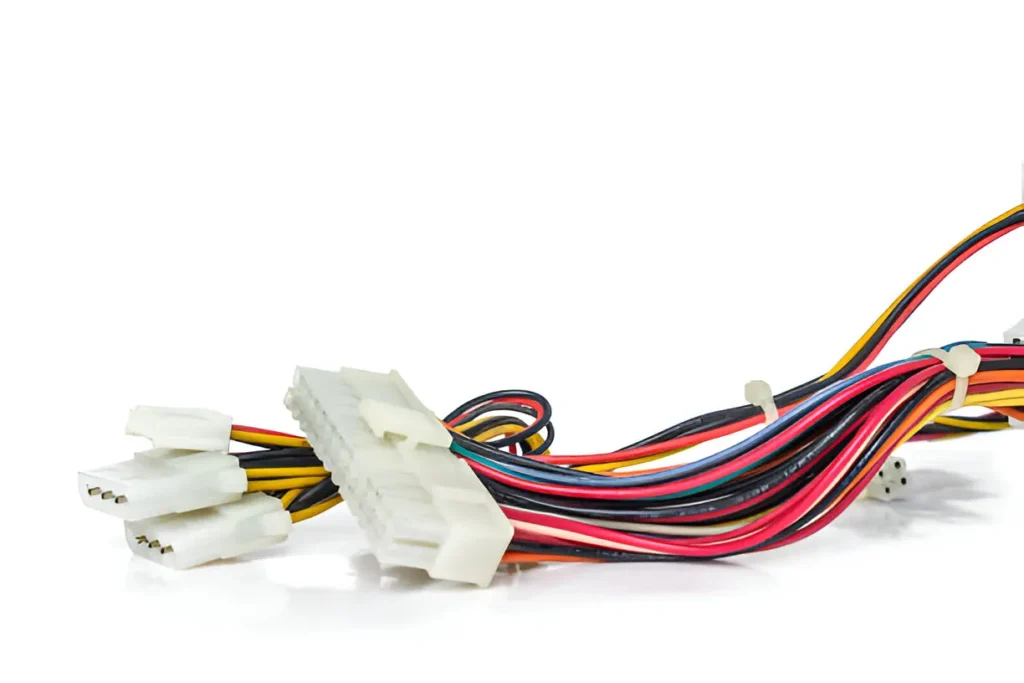

Ever wondered how to streamline your vehicle’s wiring system?Car zip ties offer an efficient solution for optimizing automotive wiring harness and component fixation.These versatile fasteners provide strength, durability, and ease of use, making them ideal for organizing and securing electrical components in vehicles.In this post, we’ll explore practical techniques to leverage nylon cable ties for enhanced automotive wiring management.

Zip ties on car offer exceptional strength and durability, making them ideal for automotive wiring applications. These ties can withstand the constant vibrations and harsh environments found in vehicles. Their robust construction ensures that wiring harnesses remain securely fastened, even under extreme conditions.

Automotive environments expose wiring to various chemicals, extreme temperatures, and UV radiation. Car zip ties excel in resisting these factors. They maintain their integrity when exposed to automotive fluids, oils, and lubricants. Additionally, their resistance to heat, cold, and UV exposure ensures long-lasting performance in diverse climates.

The flexibility of Car zip ties allows for effective bundling of wires in tight spaces within vehicles. Their self-locking mechanism provides secure fastening, preventing loosening due to vibrations or movement. This ensures that wiring remains organized and protected throughout the vehicle’s lifespan.

Compared to other harnessing solutions,zip ties on car offer a cost-effective option for automotive wiring management. Their low cost, combined with easy installation and long-lasting performance, makes them an economical choice for vehicle manufacturers and mechanics alike. This cost-effectiveness does not compromise on quality or reliability.

Factors to consider: tensile strength, temperature range, UV resistance, flammability rating

Common types for automotive use:

Specialty designs: releasable, identification tags, push mounts, fir tree mounts

Choose the right size and strength for each application. Keep wires away from heat sources and sharp edges. Group wires appropriately. Space cable ties at regular intervals. Use mounting hardware for secure connections. Tighten but avoid excessive compression. Cut off excess cleanly. Label bundles for easy identification.

zip ties for car are resistant to vibration, heat, and chemicals. They hold wires and components securely in place. This prevents movement and wear. Proper bundling protects wires from environmental factors. Cable ties with UV resistance maintain strength when exposed to sunlight. Secure fastening reduces stress on connectors and terminals.

zip tie car are lightweight and reduce the overall weight of the vehicle. This can improve fuel efficiency. Many nylon cable ties are recyclable. Some manufacturers use recycled nylon in production. Durable cable ties reduce the need for frequent replacement. Proper wire management extends the life of electrical components. Biodegradable options are gradually becoming more sustainable practices.

Nylon cable ties are inexpensive compared to other fastening methods. They can be installed quickly and easily, saving labor time. Standardized sizes reduce inventory complexity. Reusable cable ties reduce waste. Proper wire management prevents expensive electrical issues. The durability of cable ties reduces maintenance and replacement costs. Lightweight cable ties help improve the overall efficiency of the vehicle.

Car zip ties offer a robust, versatile solution for optimizing automotive wiring harness and component fixation. Their durability, flexibility, and cost-effectiveness make them ideal for various vehicle applications.

Proper installation techniques ensure long-lasting performance and enhanced safety in automotive electrical systems.

Implement these cable tie best practices to improve your vehicle’s wiring organization and reliability.