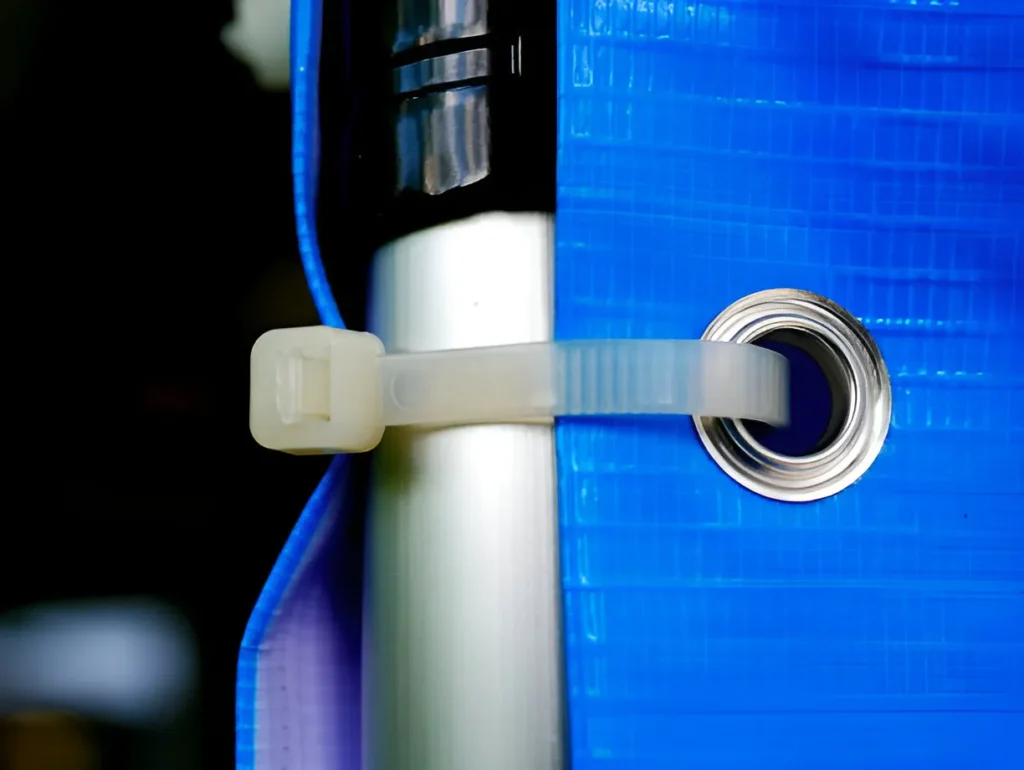

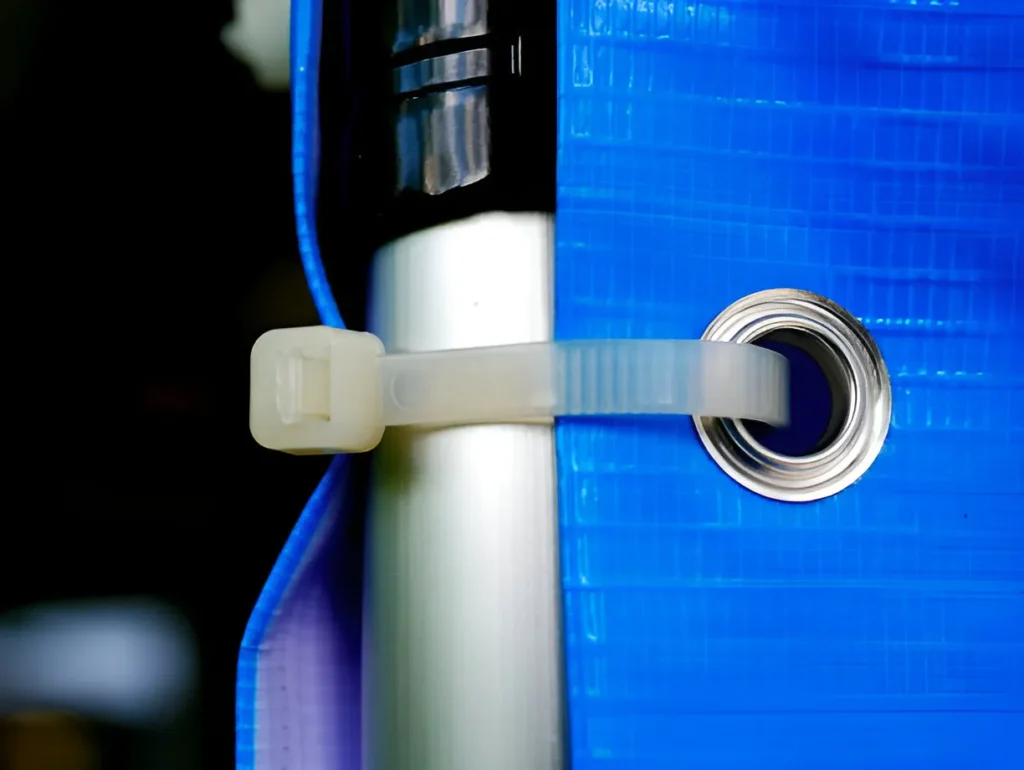

How long is the service life of zip ties cable ties

how long do zip ties last outside

阅读更多

Moisture significantly impacts nylon wire ties. This article explores the nature of nylon 6.6, its hygroscopic properties, and how humidity affects nylon tie wire performance.

Nylon 6.6 is a high-performance synthetic polymer made from the polymerization of hexamethylenediamine and adipic acid.

It has excellent mechanical strength, heat resistance and dimensional stability and is widely used in industry and daily life.

The melting point of nylon 6.6 is about 264°C, which is higher than nylon 6, making it perform better in high temperature environments.

Nylon 6.6 is a hygroscopic material that absorbs and releases moisture from the surrounding environment.

This property causes the performance of nylon wire ties to change with changes in ambient humidity.

Under normal conditions,nylon zip ties usually contain 2-3% moisture, which helps maintain their flexibility and strength.

Humidity has a significant effect on the properties of nylon wire ties:

Moderate humidity can actually improve some of the mechanical properties of nylon zip ties:

Understanding the effects of moisture on nylon cable ties is crucial for their optimal use and storage.

While humidity can impact their strength and flexibility, proper storage and handling techniques can help maintain their performance.

By considering environmental factors and following best practices, users can ensure the longevity and reliability of nylon wire ties in various applications.