Ever wondered how to choose the perfect cable tie for your project?

This Cable Tie Size Guide will demystify the process of selecting the right cable tie dimensions.

From length and width to bundle diameter and tensile strength, we’ll explore the key factors that determine the ideal cable tie size for your specific needs.

How are cable ties measured?

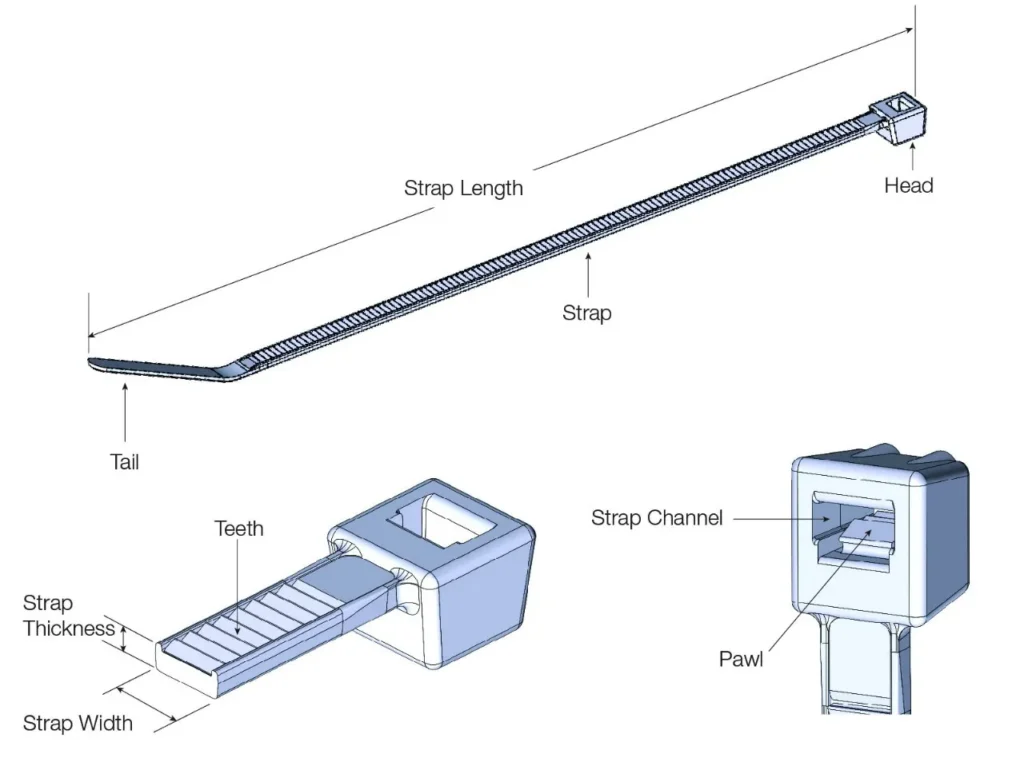

Cable ties are measured using several key parameters.

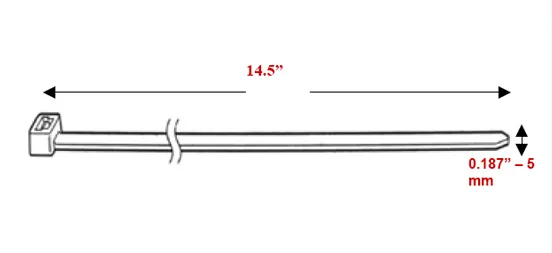

The length of a cable tie is determined from the tip to the head, typically ranging from 100mm to 1500mm.

Width measurements refer to the strap’s breadth, usually between 2.5mm and 12mm.

What size do cable ties come in?

Cable ties are available in a wide range of sizes to suit various applications. Lengths typically range from 80mm (3 inches) to 1530mm (60 inches). The width of cable ties varies from 2.5mm to 12mm, with wider ties generally offering higher tensile strength.

Common cable tie lengths include 100mm, 200mm, and 300mm. These sizes are suitable for most household and light industrial uses. For larger bundles or industrial applications,

longer ties up to 1530mm are available.

What is bundle diameter?

Bundle diameter refers to the maximum circumference of a group of cables or wires that a cable tie can securely fasten. This measurement is crucial for selecting the appropriate cable tie size.

Group the cables or objects to be fastened, and measure the widest point using a flexible measuring tape or caliper to determine the bundle diameter.

Cable tie manufacturers specify the maximum bundle diameter for each tie size. This information helps users choose ties that can effectively secure their cable bundles without being too small or excessively large. For example, a cable tie with a maximum bundle diameter of 4.330 inches can securely fasten cable bundles up to that size.

Accurate bundle diameter measurement ensures proper cable management, preventing issues such as loose fastening or unnecessary material waste. It also contributes to the overall safety and efficiency of cable installations in various applications, from household use to industrial settings.

What is tensile strength?

Tensile strength measures a cable tie’s ability to withstand stress without breaking, stretching, or deforming. It represents the maximum force or load a cable tie can bear before failure. Tensile strength is typically expressed in kilograms (kg), pounds (lbs), or newtons (N).

For cable ties, tensile strength varies based on material composition and dimensions. Nylon cable ties offer tensile strengths ranging from 8 kg for 2.5mm wide ties to 114 kg for 12.7mm wide ties. Stainless steel cable ties provide higher tensile strengths, reaching up to 166 kg for 7.9mm wide ties.

Manufacturers specify the minimum loop tensile strength, indicating the load capacity the looped portion of a cable tie can withstand. This value helps users select appropriate cable ties for their specific applications, ensuring secure fastening and preventing failure under anticipated loads.

When choosing cable ties, consider the environment and intended use. Factors such as temperature, chemical exposure, and UV radiation can affect a cable tie’s performance and durability.

How to choose the right cable tie size

Selecting the appropriate cable tie size involves considering several key factors. The primary considerations include the bundle diameter, tensile strength required, and the specific application environment.

Measure the bundle diameter of the cables or objects to be secured. This determines the minimum length of cable tie needed. Choose a tie that can comfortably wrap around the bundle with some extra length for securing.

Assess the weight of the items to be fastened. The cable tie’s tensile strength must exceed this weight. For heavy loads, consider using multiple ties or selecting ties with higher tensile strength ratings.

Evaluate the environmental conditions where the cable ties will be used. Factors such as temperature, UV exposure, and chemical presence can affect the tie’s performance. Select materials suitable for these conditions, such as UV-resistant nylon for outdoor use or stainless steel for high-temperature environments.

Consider the width of the cable tie. Wider ties generally offer higher tensile strength and are better suited for heavier loads or applications requiring increased durability.

For critical applications, factor in a safety margin by choosing ties with tensile strengths higher than the minimum required. This ensures reliable performance and longevity of the fastening solution.

FAQs

Q1:What size cable ties do I need?

Choose a cable tie that fits the diameter of the bundle. Consider the length and width of the tie based on the size of the bundle.

Q2:How many kg can a cable tie hold?

Cable ties have varying tensile strengths, typically ranging from 8 kg to 114 kg for nylon ties and up to 166 kg for stainless steel ties.

Q3:How tight should cable ties be?

Tighten cable ties firmly but not overly tight. Leave some slack to allow for movement and avoid damaging the cables. Use a proper tensioning tool to ensure the right tension.

In Conclusion

Choosing the right cable tie size is crucial for secure fastening and reliability.

Consider key factors such as length, width, and tensile strength to ensure optimal performance.

Assess your needs and select the right cable ties for your project today.